Welcome to Shandong Leto Automobile Technology Co., Ltd

Views: 0 Author: Li Publish Time: 2025-12-15 Origin: Site

In a significant move towards sustainable manufacturing, SAIC-GM-Wuling (SGMW) has announced a groundbreaking initiative to integrate bamboo fiber materials across its vehicle interiors. The company has set an ambitious target: to gradually equip its entire model lineup with this eco-friendly material by 2026. This "bamboo instead of plastic" strategy marks a major step in redefining what eco-conscious manufacturing means for the modern automobile, particularly within the popular and fast-growing electric vehicle segment where SGMW is a key player.

This isn't a distant concept; bamboo fiber has already received its official "automotive passport" at SGMW. The material, with a remarkable bamboo content of up to 75% in composite panels, offers a density nearly half that of traditional plastics. This breakthrough means that components like dashboard trims, door panels, and various interior trim pieces can now be crafted from a rapidly renewable resource. For consumers, this translates into a lighter, cleaner, and more natural cabin environment in their next new energy car.

The shift to bamboo fiber is driven by a powerful combination of environmental, technical, and user-experience benefits that align perfectly with the ethos of the modern battery car.

Substantial Weight Reduction and Efficiency Gains: One of the most immediate technical benefits is weight savings. The use of bamboo fiber composites can reduce the weight of interior components by a significant margin. For any electric vehicle, reduced weight directly contributes to enhanced energy efficiency, allowing the car to travel further on a single charge—a paramount concern for every battery car owner and manufacturer.

A Healthier Cabin and a Healthier Planet: Beyond performance, bamboo fiber dramatically improves cabin air quality. Traditional plastics and adhesives can off-gas volatile organic compounds (VOCs) like formaldehyde. SGMW reports that bamboo fiber materials have near-zero formaldehyde emissions, creating a healthier space for occupants. From a lifecycle perspective, the material is a champion for carbon reduction, with the potential to cut substantial CO2 emissions for every ton of plastic it replaces. Furthermore, it boasts an impressive natural degradation rate, breaking down in a fraction of the time required by conventional plastics.

SGMW is implementing this technology with remarkable speed, demonstrating its commitment is more than just a promise for the future.

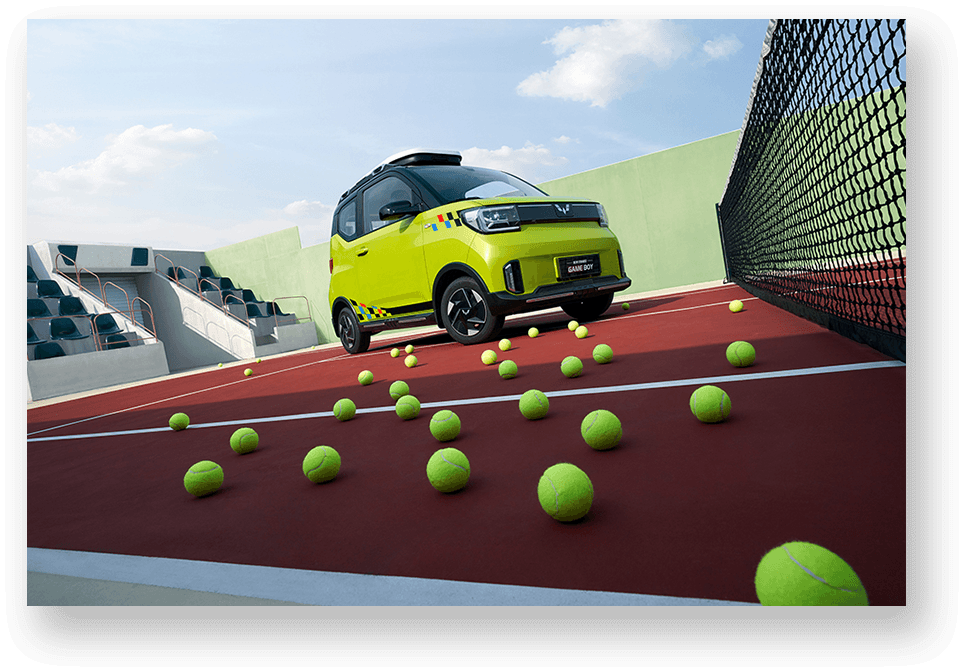

Already on the Road Today: The bamboo fiber revolution is already underway. The material has been successfully deployed in over 20 of SGMW's best-selling models. This includes popular electric vehicles like the Wuling Hongguang MINI EV and the Wuling Bingo, as well as newer models like the Wuling Xingguang and the Baojun Yunhai. This wide-scale current application proves the material's durability, feasibility, and consumer acceptance in real-world conditions for a mass-market automobile.

The Full-Scale Vision for 2026: The current rollout is just the beginning. The company's strategic plan involves a gradual phase-in across all its products. Future flagship models, such as the anticipated Baojun Huajing S, are slated to fully embrace this "bamboo instead of plastic" philosophy. The goal is clear: by 2026, a customer purchasing any new SGMW car, whether a compact urban electric vehicle or a family-oriented new energy car, will benefit from an interior crafted with this sustainable material.